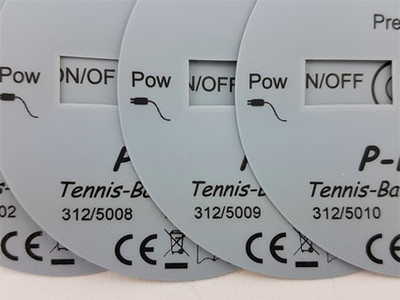

Graphic overlays with consecutive serial numbers are also possible with silk screen printing.

Graphic overlays, control panel overlays

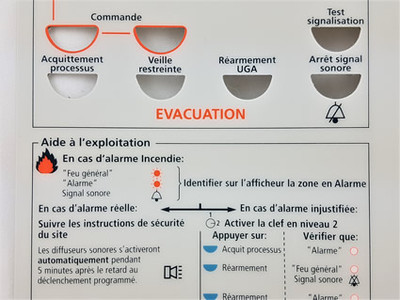

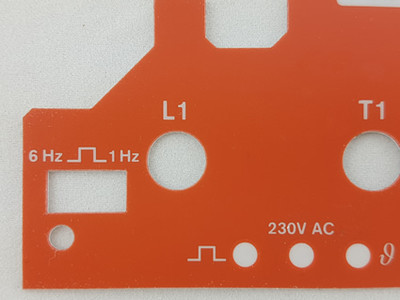

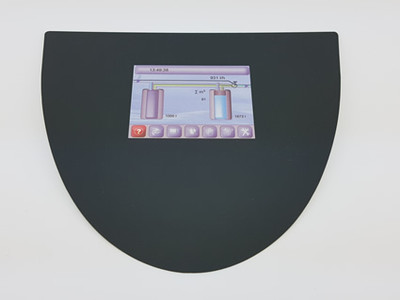

Graphic overlays and control panel overlays made from polycarbonate or polyester, printed in several colours, self-adhesive, embossed, lasered or plotted, with matted or transparent display windows for displays or LEDs according to customer specifications. The graphic overlays produced by us are used in automotive and mechanical engineering, in household appliances and appliances for medical technology, as well as in devices for measurement, steering and control technology. Graphic overlays are a simple and cost-effective alternative to printed or engraved front panels. Mostly made from polycarbonate, and more rarely from polyester, they are printed on the rear side in silk screen or inkjet printing and provided with adhesive.

Description

The print (labelling, graphic) on the rear side of the film protects it from abrasion and fading caused by mechanical, chemical and environmental influences caused by the weather. Later illegibility of the writing is prevented. Visually, it gives the impression of high quality, not least because of the graphic design of the entire front panel.

The adhesive is either attached by laminating an adhesive film (e.g. 467MP or 468MP of 3M) from the transfer adhesive strip or by printing a silk screen-printed adhesive onto the rear side of the film. In cases where there are many different languages, storing the graphic overlays is more cost-effective than the provision of printed or engraved front panels or even entire components. Thanks to the reduced number of binding variants achieved by this, logistics costs are also reduced.

The customised product finalisation thus only takes place in the final assembly.

Only partial areas of the front panel can be labelled with graphic overlays. Even when it comes to this, flexibility with several variants and protection from later illegibility is retained. Noteworthy areas, such as a company’s own logo, can be designed with doming elements.

With the 3D effect that can be achieved with this, the front film visually appears more elegant and of higher quality. This is the preferred method for graphic overlays because of the high level of impact and scratch resistance, as well as the better heat deflection temperature of polycarbonate compared to polyester. If the maximum thickness of biaxial-oriented polyester films is approx. 280 µm, then even higher levels of thickness can be achieved with polycarbonate.

Choose from ultra-fine matt, fine matt, matt, brushed and polished (with a hardened surface) on surface structures.

During the extrusion process, the surface structure of the polycarbonate film is shaped by roll cylinders. For the polyester film, the surface structure is raised by applying a UV textured paint in a downstream coating process. Well-known refiners include MacDermid Autotype, Folex and Coveris Advanced Coatings.

By adding UV stabilisers (UV absorbers), the weather and ageing resistance for use outdoors is increased. UL94 (V-0, V-1, V-2, HB) classified flame-retardant types of film are also available, which are often used in electronic devices for shipment to the USA.