An adhesive-free edge prevents the adhesive compound from being pushed out over the punched line, and the punched part and punching die from being contaminated.

Adhesive printing

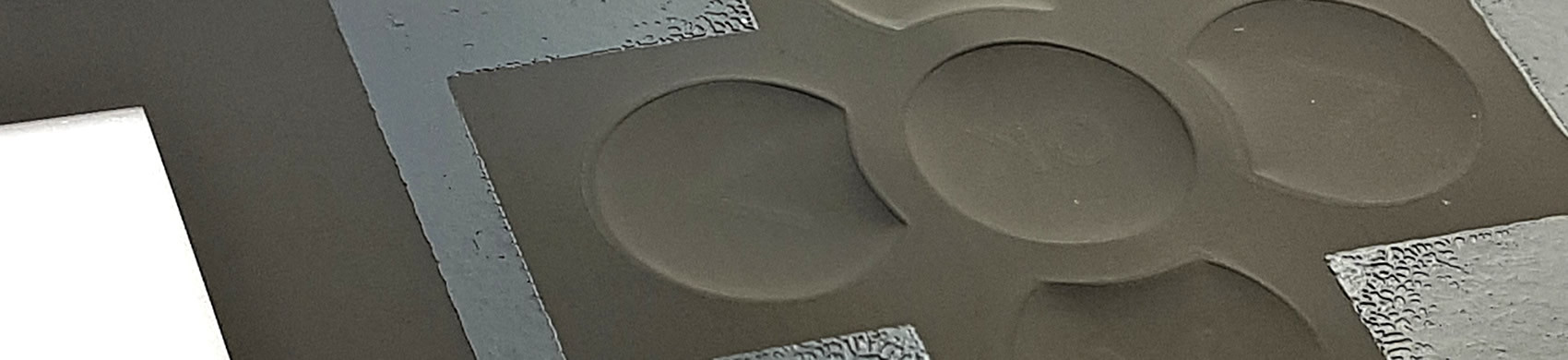

We print dispersion and acrylate-based adhesives using silk screen printing. With adhesive printing, any adhesive surface layouts can be realised, which is not the case with adhesive films from transfer tapes in terms of manufacturing technology. Films positioned inaccurately can be easily repositioned, as the films can be removed without leaving behind any residue from the adhesive and are reusable. We print the adhesive and cover the adhesive layer entirely with silicon paper.

Description

Thanks to the full coverage, adhesive-free areas, such as display windows, are protected from dirt and scratches. There are suitable silk screen-printed adhesives with different peel values for all common substrates.

The necessary thickness of the adhesive layer can be adjusted individually to the surface structure to be stuck to as well as to the material properties. Cohesion (internal strength) or adhesion (surface adhesion), what keeps the glued parts stuck together? The adhesive strength results less from the adhesive forces because of the cohesion forces.

Deciding on which one to apply depends on the type of adhesive used and on the materials that are to be bonded together and their surface structures. Mechanical adhesion predominantly works for adhesion on rough surfaces. The adhesive ‘interlocks’ with the surface. Predominantly cohesive forces have an effect with diffusion adhesives. The adhesive penetrates the material. Adhesives form a real bond to the substrate when it reacts chemically with the surface.

In cases of smooth surfaces, the adhesive strength is achieved with absorption forces, the absorption adhesive.